Insulation Worldwide

Damplate sheet

Damplate sheet

Prices are based on square metre units.

Share

Collapsible content

Description

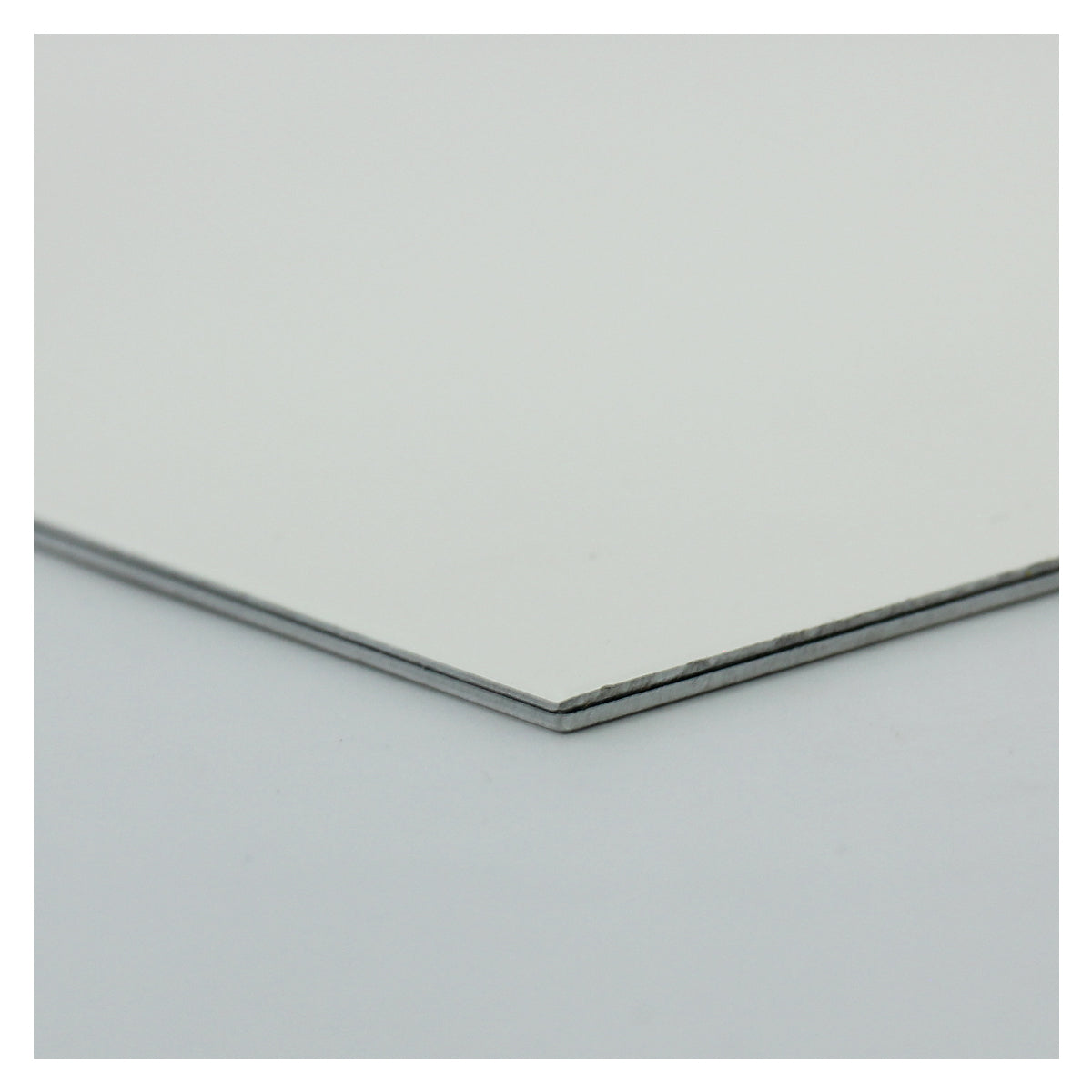

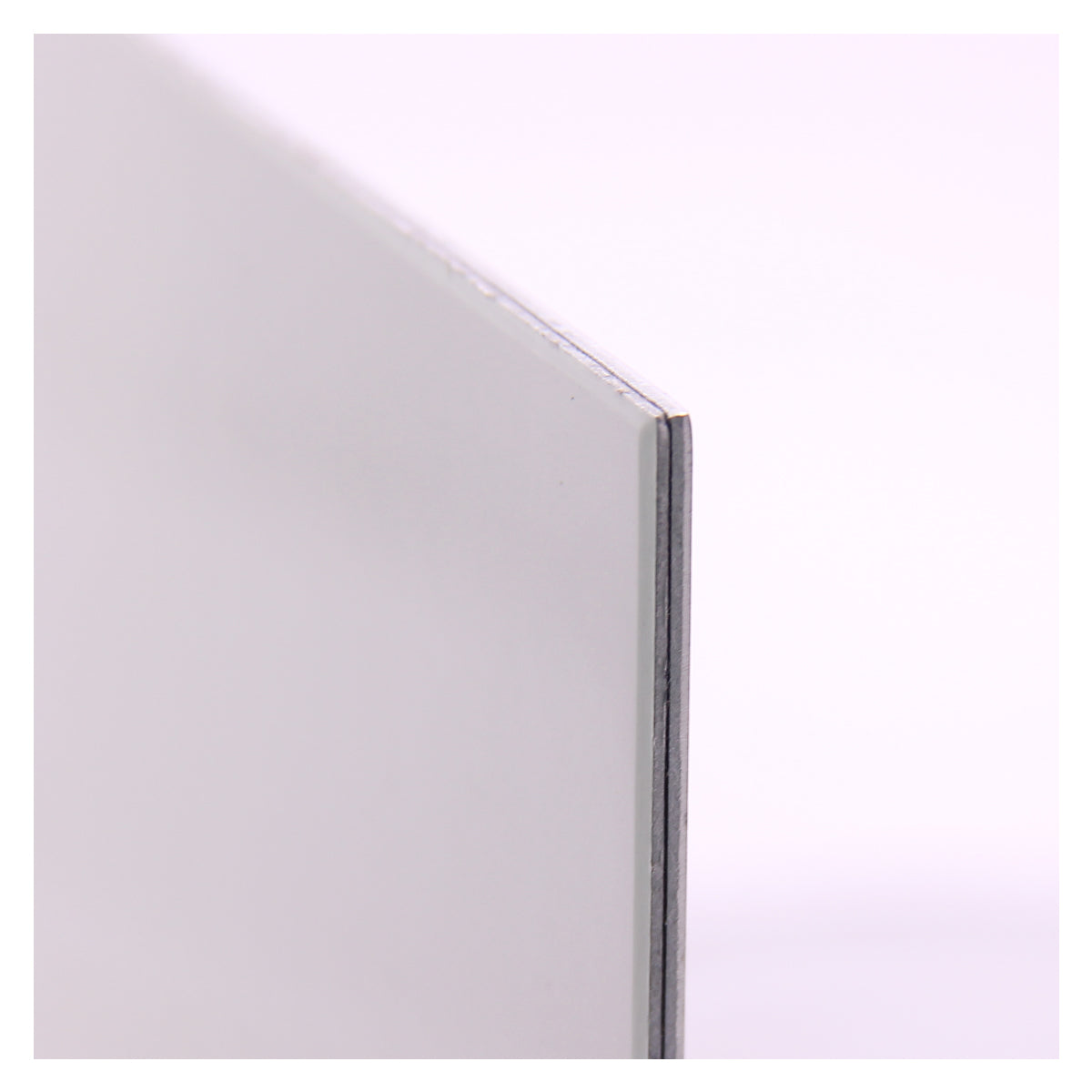

Damplate is a sandwich sheet consisting of two galvanised steel or aluminium (EN AW 5754/H22) plates with a viscoelastic layer. Two plates are not touching each other due to visco elastic layer in between the two plates. Damplate® is the right choice for steel or aluminium structures, and its components are subject to vibrations that are transmitted as structure-borne sound waves. This composite material displays high structure-borne and airborne sound damping properties and particulary designed for reducing acoustic loads where noise avoidance or damping is either uneconomical or impossible for design reasons. The viscoelastic core layer absorbs vibrations by allowing slight relative movement between the cover sheets and converting the vibration energy into heat. Compared with conventional steel or aluminium, damplate® can reduce structure-borne sound levels by up to 20dB.

FEATURED PROPERTIES

- Excellent damping ratio. The damping loss factor is greater than 0.426.

- For skin-damping lightweight solution, Superior acoustic insulation performance above 20dB

- Two versions of the product are available for application purposes for steel and aluminium surfaces.

- Electrostatic dry powder coating surface (standard RAL9010. Other colour upon request)

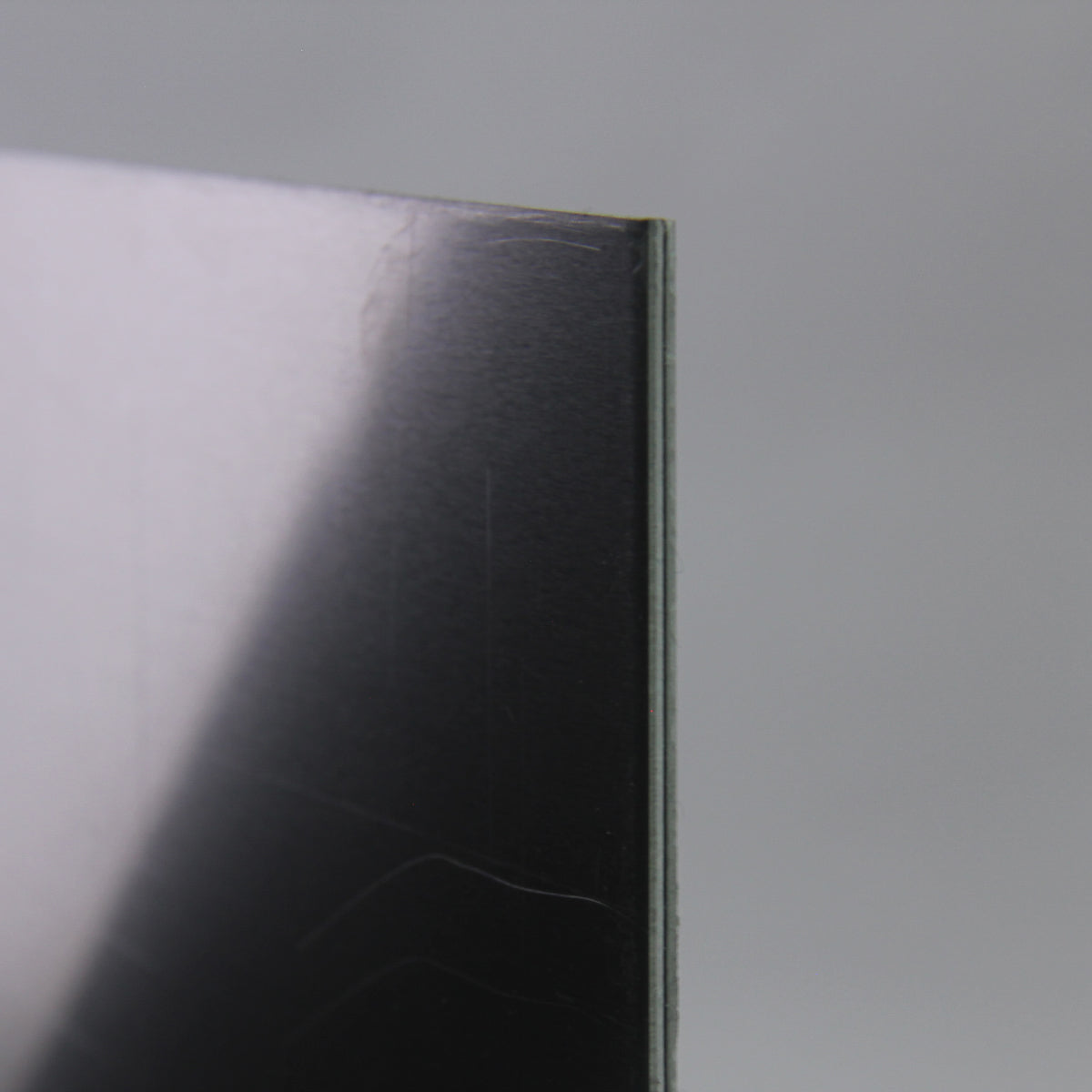

- Protective foil for coating surface Fire resistant viscoelastic layer EN AW 5754 (H22) aluminium and galvanized steel sheets

- Easy to install and quicker application process.

- Extended operating temperature range (-20 200 ºC)

- May be formed by shaping machine.

MATERIAL CHARACTERISTICS

Core layer of damplate® is made of a viscoelastic resin. When the composite sheet subject to flexural vibrations, there is slight relative movement between the cover sheets which results in periodic shear deformations in the viscoelastic interlayer. The internal friction generates in the resins and causes vibrational energy to be “ lost/converted” as mechanical energy, i.e. it is converted into heat; this dampens vibration in the composite sheet. Within the working range( 25-50 ºC), the material achieves optimal vibration damping through a correspondingly high loss factor.

PROCESSING

Joining

Damplate® may be united by all common joining techniques. Mechanical methods include joining with screws or rivets, but also folding and clinching. Adhesive bonding, resistance and fusion welding are other commonly used methods. Most mechanical joining techniques commonly used with standard metal sheet can be applied to the composite material without tooling modifications. The strengths of the resulting joints are in the same order of magnitude as those obtained with steel sheet. Screws require tightening to a specific torque, and it should be noted that the viscoelastic interlayer, which exhibits viscoelastic properties in the specified temperature service range, will yield locally under the resulting pressure. Damplate® can be riveted both manually(e.g using hand-held riveting tongs) and with automatic machinery. Conventional riveting (from both sides) and blind riveting have both given good results. Self-piercing/riveting techniques with solid and semi-tabular rivets may also be used. Adhesive bonding eliminates ( or at least greatly reduces) the thermal and mechanical loading, similar to other joining methods. Damplate® is suitable for adhesive bonding, and it is generally equivalent to a steel or aluminium sheet and of identical surface quality. Although it is important to note that only one of the cover sheets is involved in the joint.

Cutting

Cutting processes are known to yield good results with Damplate®, including mechanical methods such as shearing, punching, blanking, and drilling, as well as water jet cutting.

Coating

Typical pretreatment and painting processes (electrocoating) can be used without impairing the baths. Damplate® can be painted like standard steel and aluminium sheet. To prevent run-out the overheating temperatures should not exceed the admissible limits. damplate® will resist these temperatures without interlayer bleed-out, cutting edges, or decomposition of the viscoelastic layer.

Recycling

The Damplate® core interlayer has a maximum nominal thickness of 0,100 mm, allowing damplate® to be recycled or disposed of in the same way as painted steel and aluminum scrap. It does not have to be treated as hazardous waste.

PROCESSING

This product is mainly applied as a (sheet) construction in the machine construction, yacht and shipbuilding, dumping bunkers, partition walls, floors, footbridges, pipeline insulation and numerous other applications. Additionally, it is used on oil sumps, valve and transmission covers and dash panels. Damplate is available in two variants, depending on the application purpose, in numerous metal grades (steel or aluminium).

Technical Specifications

Shipping & Delivery

Shipping is free for orders of 120 m² and above. For orders below 120 m², the shipping cost will be calculated accordingly. Please contact us for more details.